Sheathed Heaters

Sheathed heaters play a vital role in toaster ovens, microwaves, air conditioners and other household electronic devices requiring a heating element. They also play a critical role in industrial driers, train heating systems and other places normally invisible to the general public. Sheathed heaters have a spiral-shaped heating wire, held in the center of a metal tube made from our NAS800L or NASH840 , and the tube is filled with compressed electrical insulating powder. Because of the hot temperature involved, our products are ideal choices given their resistance to high-temperature oxidation and superior creep strength.

Heat-Treating Furnaces

Heat treatment furnaces for providing heat treatment in a wide range of applications are exposed to high temperatures for long periods of time. A furnace material must therefore be selected that can handle high-temperature oxidation, high-temperature corrosion, high-temperature gas corrosion and creep. Although SUS310S may be used in the open air, a nickel-base super alloy is often required in an environment filled with corrosive gases. To meet these needs, we have developed the Incoloy®products NAS800 and NAS825 along with the Inconel®products NAS600 and NAS601 .

* Incoloy and Inconel are registered trademarks of Special Metals Corporation.BA (Bright Annealing) furnace

Heat treatment of stainless steel and other metals is often performed in a vertical bright-annealing (BA) furnace in which a metal muffle is used. The muffle is heated up to 1150ºC and therefore must be made of a material with high oxidation resistance. Also, it is required to have excellent creep properties. The reason for this is that the muffle furnace is about 15 m in overall height and more than 3.5 tons in weight, and it is fixed at the top and suspended, causing creep deformation by its own weight. NAS600 and NAS601 are used in a severe environment such as this.

(NAS600, photo taken in 2017)

Long-term operational performance of BA furnace

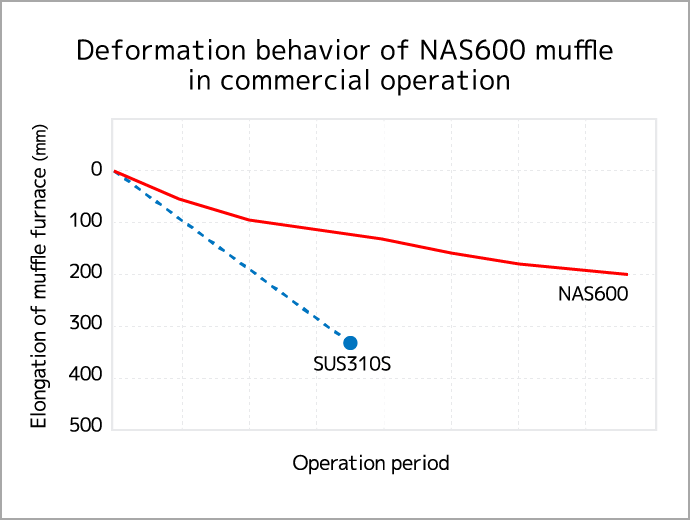

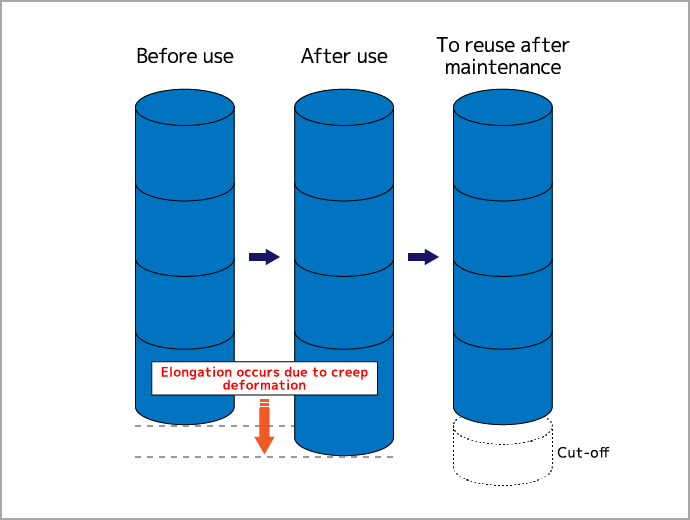

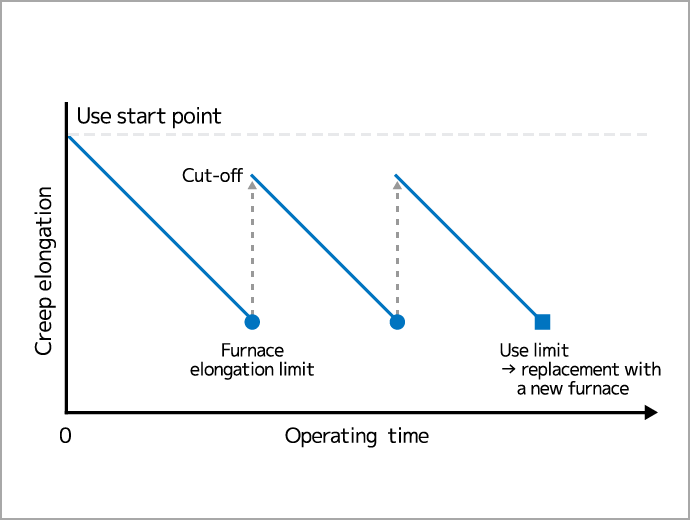

When used for an extended period of time, the muffle is subjected to creep deformation and must be dismantled and cut off at the bottom if the deformation proceeds. For example, a muffle made of SUS310S is elongated about 360 mm per year. It is known that the deformation is accelerated by shutting down and restarting the furnace.

The frequency of maintenance is expected to be reduced if the muffle is made of NAS600, which has excellent creep properties. The figure below shows the results of the deformation of a muffle that is made of NAS600 and has been used for commercial production for more than two years. The deformation is less than half of that of SUS310S. The muffle has been used without being cut off, not even once. The muffle made of NAS600 has been proven under severe conditions in which the furnace is frequently shut down and restarted.

| Total operation period: more than 2 years <Commercial operating conditions> |

|

|---|---|

| Operating temperature | 600~1100℃ |

| Materials | SUS304,SUS301 etc. |

| Atmosphere gas | AX gas |

| Number of shutdowns | 78 (high frequency) |