Membranes for LNG Tankers

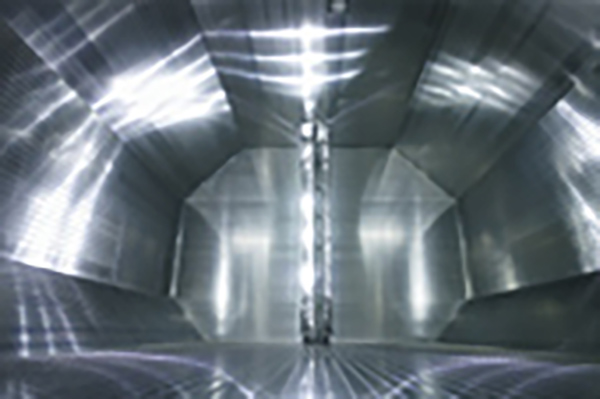

To transport natural gas from the country of origin, it is first cooled and converted to a liquefied form called LNG (liquefied natural gas), and then transported in tankers. The tankers must be insulated to maintain the cold temperature required for LNG in its liquid state as well as being capable of withstanding the extremely cold temperatures. NAS36LG was developed for the inside of the box-like membrane tanks, providing the advantages of an extremely low coefficient of thermal expansion and the capability to control thermal stress caused when the temperature varies. NAS36LG plays a vital part in the safe transport of LNG.

Radiation Shielding

Our NAS8R10 product is a stainless steel made from an SUS304 or 304L base with boron added to provide strong neutron absorption power. NAS8R10 is strong and strongly resistant to corrosion. Applications include racks and casks for storing and transporting used nuclear fuel rods.

Electrical Contacts

If you open up your mobile phone, you will see gold electrodes that are in contact with the battery. Those electrodes are pure nickel with gold plating that undergo a bending process. Nippon Yakin's NASNi201 is a pure nickel material not only providing low electrical resistance but superior molding properties, making it ideal for battery electrode terminals. Although a very different form of electrode, NASNi201 is also used as the pure nickel in electrolysis cells used to color the aluminum sashes used for windows.

Hoop Coils for Weld Overlays

Hoop coils is a material used for the overlay welding of metal strips. Used to cover the surface of structural metal to provide a high level of corrosion and abrasion resistance, hoop coils is used in such applications as chemical plants. Its metal composition, however, makes it susceptible to cracking during the welding process. To avoid cracking, delta-ferrite (δ-ferrite) may be added to the welding metal. However, adding δ-ferrite causes a degradation in the hot workability, making the manufacturing process difficult. Using advanced heating and cooling control technologies along with careful regulation of special elements in the composition, Nippon Yakin has developed a manufacturing method for hoop coils that permits a large quantity of δ-ferrite without workability issues.