Melting and Refining

Simply melting and casting the raw metallic materials from scrap metal is not enough to get a good quality alloy.

management of the amounts of impurities in the raw metallic materials is needed.

Beyond this, refining is needed to reduce and adjust the carbons, gas components (oxygen), and sulfurs that cannot be removed through material management.

This process also minutely controls the amounts, properties, and shapes of nonmetallic components.

Our accomplishments have been recognized globally, and in 2002 we received the John Chipman Award from the US Iron and Steel Society.

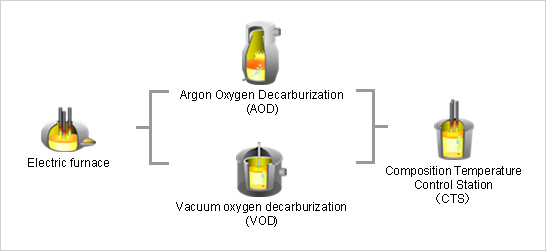

The basic construction of an electric furnace is shown in the simplified diagram above.

Electric arcs occur between the graphite electrodes and the metal.

After adjusting its components and temperature, the molten metal is moved on to the next process, refining.

Refining

At the heart of Nippon Yakin Kogyo’s refinement process is an advanced AOD (Argon Oxygen Decarburization) furnace that can refine up to 70 metric tons of molten steel. A mixture of argon and oxygen gases is piped into the AOD furnace filled with molten steel, causing carbon and other elements to burn, which raises the temperature of the steel. This makes it possible to introduce other materials to create the desired product with great precision. Nippon Yakin Kogyo also uses a variety of technologies to control minute quantities of sulfur, oxygen, nitrogen and other elements in our steel products. We also use vacuum oxygen decarburization (VOD) to remove carbon from steel.

The John Chipman Award

It is necessary to adjust inclusions in the production of High-performance Alloys consisting of many alloys to meet the productês end purpose.

In recognition of our success in this area, the US Iron and Steel Society presented our engineering team with the John Chipman Award in 2002.

The target of our control technology was to render inert nonmetallic inclusions, which are dispersed in the alloy, according to the characteristics required by the final alloy.