Hot Rolling

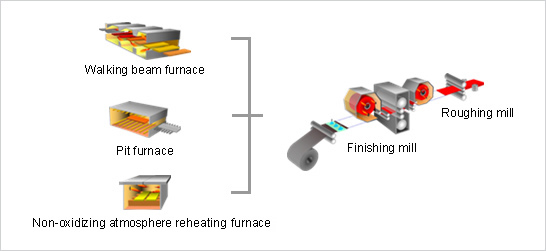

Compact but versatile, the New Compact Hot rolling mill or NCH mill is made of a rough rolling mill and a finish rolling mill. From thick plates to thin hot coils, we apply our specialized knowledge of hot rolling.

Roughing and Plate rolling Mill

Nippon Yakin Kogyo's roughing mill handles plate rolling as well as rough bar rolling for strips with sophisticated hydraulic screw down system. The original physical model of rolling of the process computer enables optimum rolling pass schedule calculations for each product.

| Primary Specifications | |

|---|---|

| Roughing Mill | four-high reverse mill |

| Roll Separating Force | 4,000 tons maximum |

| Speed | 314 m/min. maximum |

| Rolling Specifications | |

| Thickness | 220 to 6.0mm |

| Width | 2,500mm maximum |

Finishing Mill

This rolling mill is a Steckel type of reversing finishing mill capable of producing hot strips with superior thickness precision, surface quality and internal quality. This mill can roll not only stainless steels but also heat resistant alloys and steels or other high alloyed corrosion resistant alloys. The manufacture of high performance alloys encompasses a great deal of expertise such as the reheating process of alloys not containing chromium. This is particularly useful in the rolling of 36%Ni-Fe alloy and other Ni-Fe alloys and soft magnetic alloys.

| Primary Specifications | |

|---|---|

| Finishing Mill | Roll separating Force |

| Roll separating Force | 4,000 tons maximum |

| Speed | 800 m/min. maximum |

| Rolling Specifications | |

| Thickness | 25 to 2.0 mm |

| Width | 1,600mm maximum |

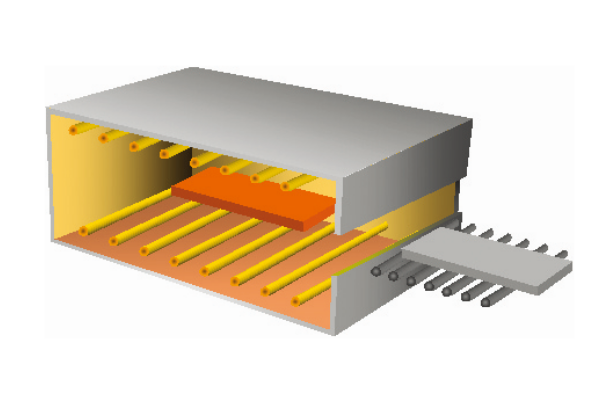

Pit furnace

The pit furnaces are used for reheating slabs for plate rolling.

The furnaces are literally shaped like pits. After the slab has been reheated, the top lid will be open and the slab is picked up and moved by the automatic crane and laid on the table for rolling.

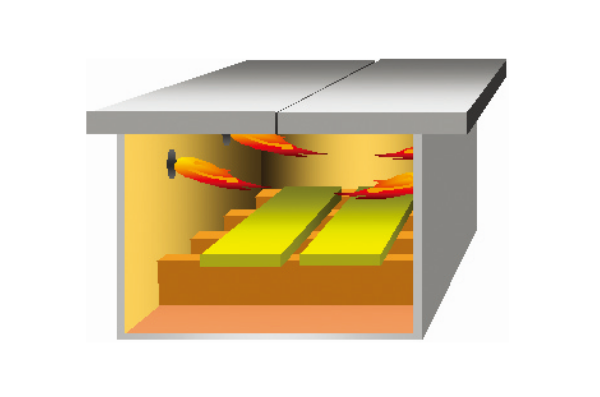

Non-oxidizing furnace

This non-oxidizing furnace reheats Ni-Fe alloys in original reducing atmosphere we developed.

Through this meticulous process, we produce high performance alloys of the best quality.