Continuous Casting

We own a vertical continuous casting machine that is as tall as a seven-story building.

Because high-performance alloys are formed through the addition of many different elements, they tend to warp severely or crack easily as they cool and harden.

Vertical equipment, then, is ideal for high-performance alloys because no unnecessary forces are applied that may warp the steel.

Casting

Casting parameters for the molten steel and alloys are adjusted so the target quality is obtained when formed into sheets.

Nippon Yakin Kogyo can produce slabs with thicknesses of 150 mm or 200 mm through our continuous casting process.

High-performance alloys consisting of a large amount of alloys are susceptible to uneven distributions of elements and depositions of special compounds. As a result, expert metallurgy knowledge is needed to realize high-quality casting and to advance to the next process.

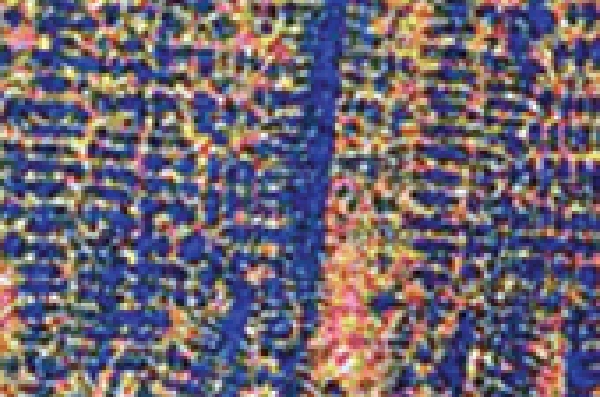

The picture on the right shows a distribution in which the elements are segregated in the cast composition.

This situation occurs as solidification advances.

Nippon Yakin Kogyo has developed state-of-the-art technology to limit this sort of segregation.

Thanks to this technology, our products receive rave reviews from our customers.