Marine Steel Structures

Marine structures are subjected to extremely harsh conditions. To build such structures, super stainless steels containing higher percentage of chromium, nickel, molybdenum and nitrogen are applied instead of normal stainless steels. Super stainless steels such as NAS254N (developed by Nippon Yakin) and NAS185N have very excellent corrosion resistance. hese materials are beneficial in terms of total cost performance due to long life and easy maintainability. NAS254N and NAS185N are remarkably suitable covering material for welding and bolting process of overlay methods.

For resistance against the marine environment, actual exposure tests have been conducted on a joint basis with various organizations. For example, in a joint test conducted with the Port and Airport Research Institute, the landscape is maintained despite exposure to harsh sunlight, violent winds and intense waves, with no corrosion occurred even after 16 years. (as of 2018)

At the Hazaki Oceanographical Research Station Observation Pier (started in 2002)

-

Long-Term Exposure Test At Hazaki Oceanographical Research Station

-

Exposure test carried out in collaboration with the Public Works Research Institute as a member of the Japan Iron and Steel Federation's Marine Corrosion and Durability Study Group

-

Exposure Test Station Simulated Marine Environment At Kawasaki Plant

-

Long-Term Use Record At The Pier For Lng Carriers

Long-Term Exposure Test At Hazaki Oceanographical Research Station

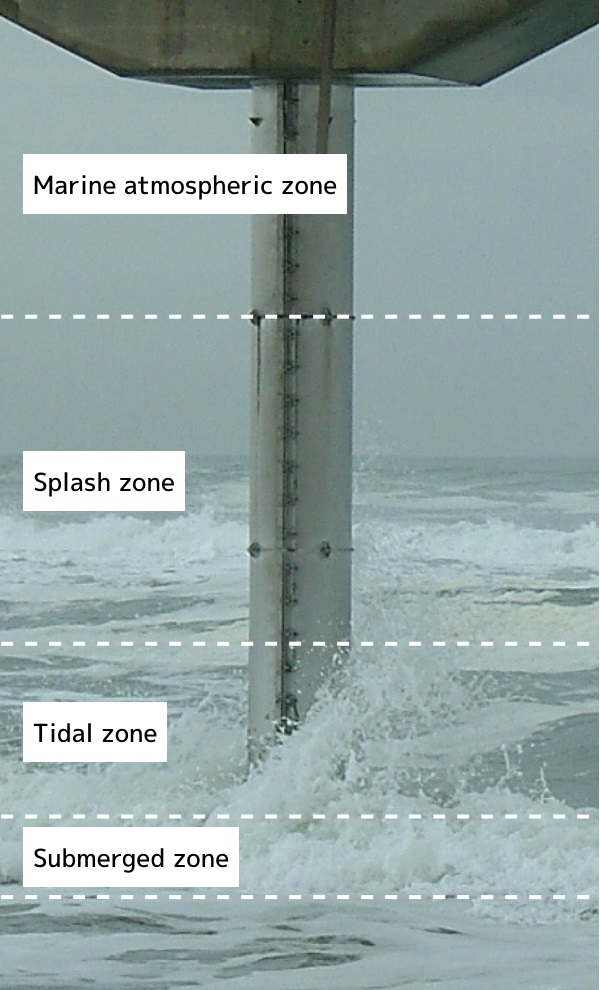

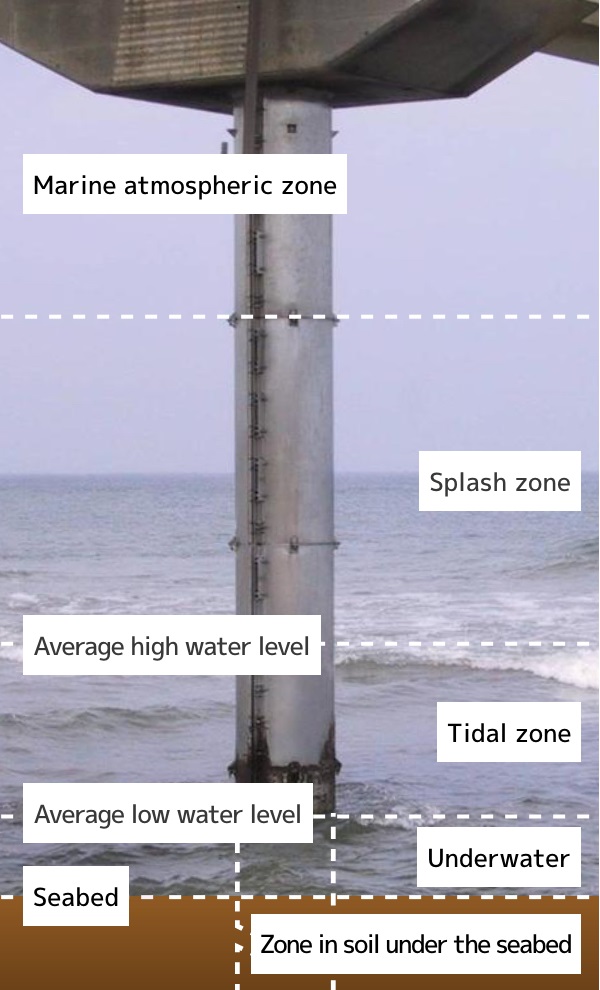

Classification of corrosion environments

Even for the same steel pipe pile, the corrosion environment will vary depending on the height. These corrosion environments are classified into the marine atmospheric zone, splash zone, tidal zone and submerged zone.

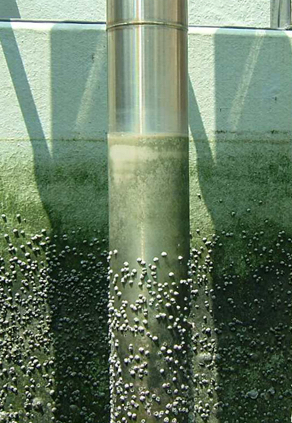

Tidal zone: NAS254N under marine organisms (no corrosion)

This is a zone that experiences repeated immersion and exposure to seawater due to the ebb and flow of the tides. Corrosion can easily occur due to marine organisms adhering to the surface (crevice corrosion).

Splash zone: NAS185N (no corrosion)

This is a zone that is continually exposed to the atmosphere and is splashed with waves. Corrosion (pitting corrosion, crevice corrosion) can easily occur due to the concentration of salt (Cl-) from the evaporation of seawater attached to the pile, and from temperature risings on the surface of the steel due to sunlight.

Long-Term Exposure Test In The Suruga Bay

Actual exposure test using the facilities of public institutions

Exposure test is carried out in collaboration with the Public Works Research Institute as a member of the Japan Iron and Steel Federation's Marine Corrosion and Durability Study Group.

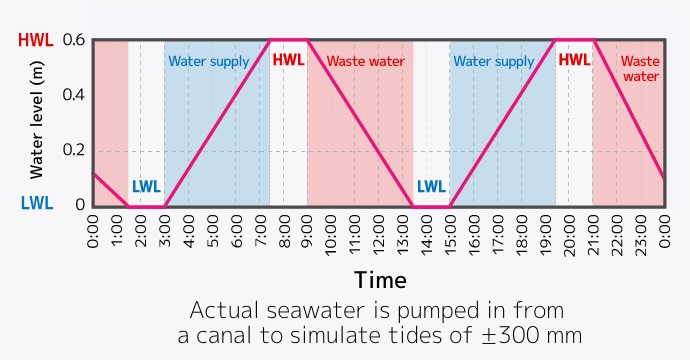

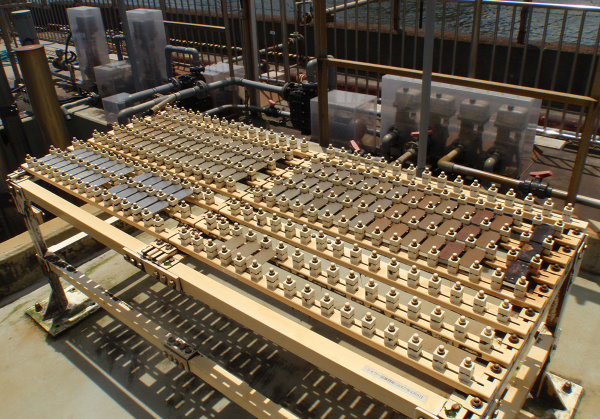

Exposure Test Station Simulated Marine Environment At Kawasaki Plant

Test plant-based data collection

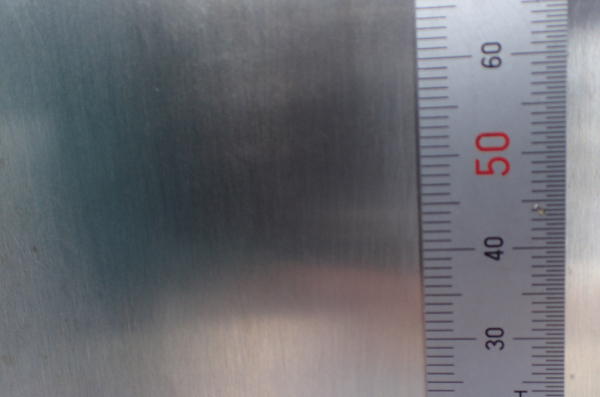

Basic data is collected at a test plant that simulates an ocean environment. Evaluation including the weld points needed to create the actual structure is ongoing.

Seawater exposure test area

(stainless steel pipe pile cover)

| After one year of exposure | NAS254N | NAS185N | SUS316L |

|---|---|---|---|

| State with marine organisms stuck to the pile |  |

|

|

| After removal of the marine organisms |  No crevice corrosion

No crevice corrosion |

No crevice corrosion

No crevice corrosion |

Crevice corrosion occurred

Crevice corrosion occurred |

Surface of weld points on various stainless steel pipe piles. Super stainless steel has excellent resistance to seawater, with no crevice corrosion forming even where barnacles have adhered to the surface, including at weld points.

Other tests

To investigate corrosion resistance of various types of steel under actual conditions, we also conduct exposure tests on small pieces inside the seawater exposure test area.

Long-Term Use Record At The Pier For Lng Carriers

Anticorrosion covers for LNG carrier berth pier

Anticorrosion covers for steel pipes made from NAS254N have been used for 29 years at a pier for LNG carriers. (Longest in the world: as of 2019)